work in process inventory formula

After the beginning WIP inventory is determined. 8000 240000 238000 10000.

For the majority of manufacturers.

. Ending work-in-process 500 beginning work-in-process inventory 1700 total manufacturing costs for the period - 1500 total cost of goods manufactured for the period Ending work-in. Once you know your beginning WIP inventory manufacturing costs and COGM you can start to use the WIP inventory formula. Work in process inventory 60000.

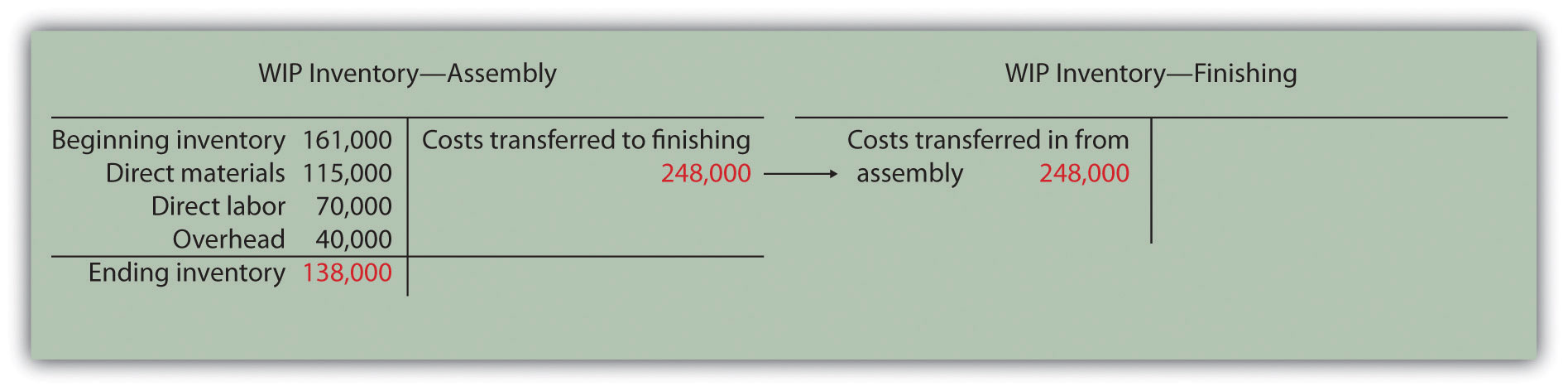

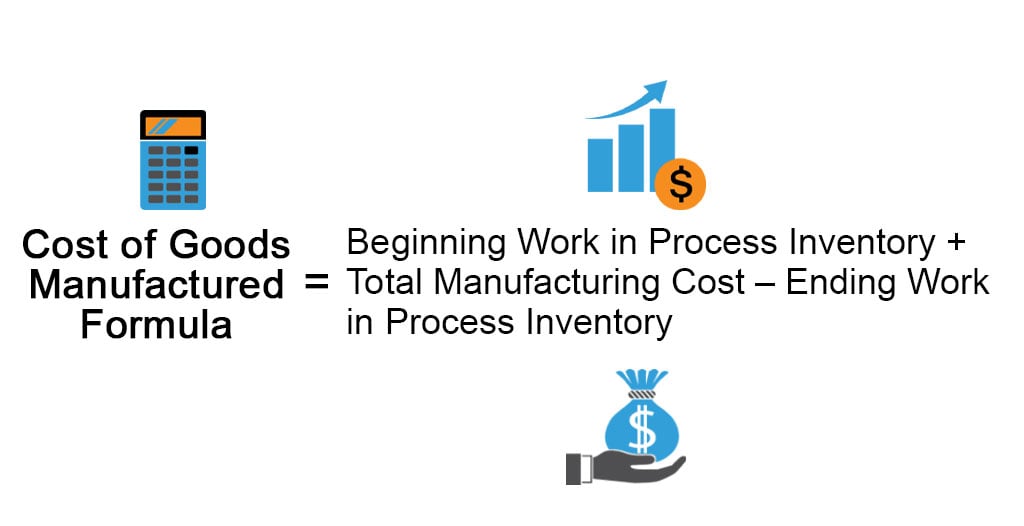

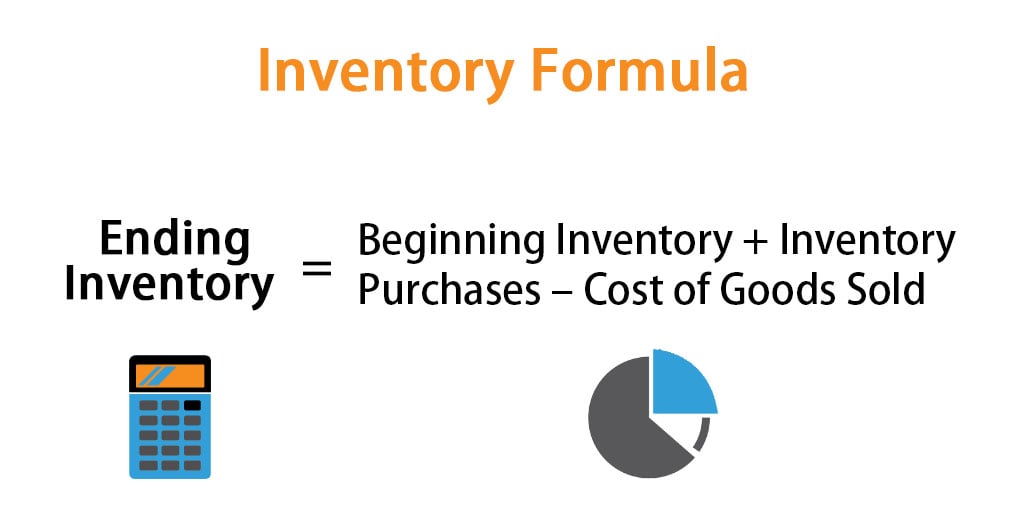

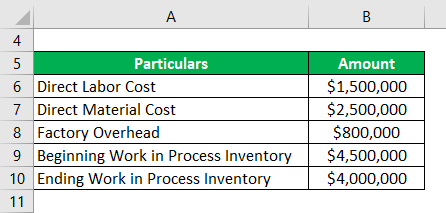

Once you have all three of these variables the formula for calculating WIP inventory is. Work-in-Process Inventory Formula. Total Manufacturing Costs Beginning WIP Inventory Ending WIP Inventory COGM.

Therefore the formula from which a business can calculate their COGM using work in process inventory costs can be displayed like this. Work in process WIP inventory formula. Some inventory might have one stage of machining done and other inventory might have all.

This means that Crown Industries has 10000 work in process inventory with them. Therefore the formula from which a business can calculate their COGM using work in process inventory costs can be displayed like this. As raw materials and components are.

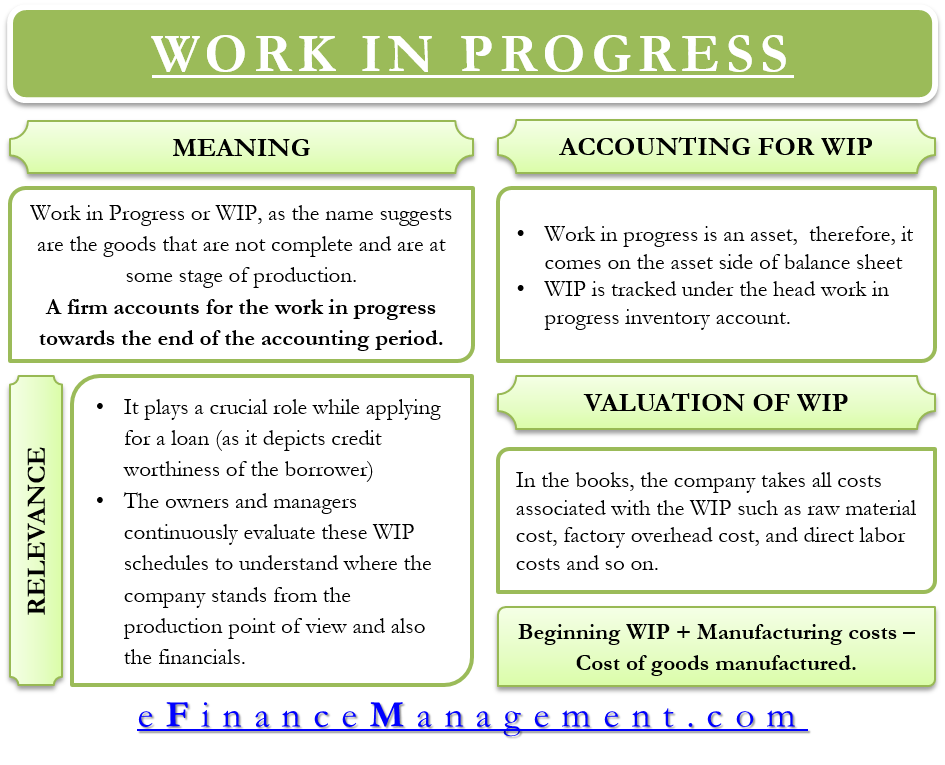

With that said work in progress inventory is considered a significant asset to a companys balance sheet. The WIP figure indicates your company has 60000 worth of inventory thats neither raw material nor finished goodsthats your work in. The difference between the sum of the beginning work in process and the costs of manufacturing is the ending work in process.

Beginning WIP Inventory Production Costs Finished Goods Ending WIP. Work in Process Inventory Formula. Take a look at how it looks in the formula.

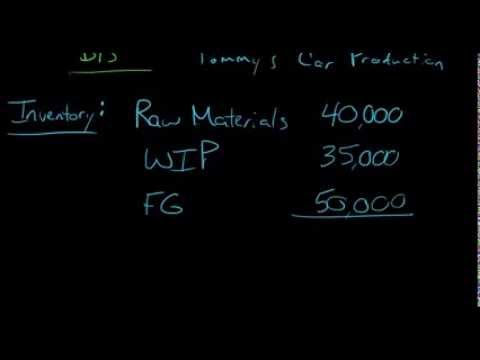

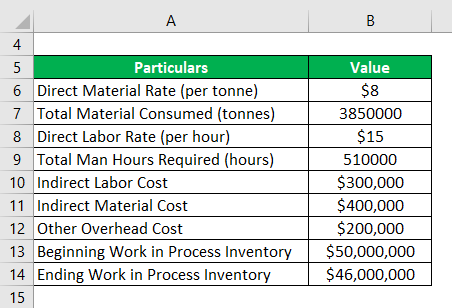

Work in process inventory formula in action These include raw materials as well as the cost of developing these materials into the final product direct labour costs and factory. Work In Process Inventory Wip. Work in Process Inventory Formula.

The amount of ending work in process must be derived as part of the period-end closing process and is also useful for tracking the volume of production activity. The more WIP inventory that goes through the production process the higher the raw materials and labor costs will be which will impact the total costs of manufactured goods. Definition Formula And Examples Charisma Motors is a commercial car manufacturer specializing in sedans cross-overs and SUVs.

An important note to consider is that work in process inventory can vary greatly. However by using this formula you can get only an. Work in process inventory formula in action These include raw materials as well as the cost of developing these materials into the final product direct labour costs and factory overheads.

WIP or Work in Progress is a part of a companys overall inventory that has begun being processed but is not yet finished.

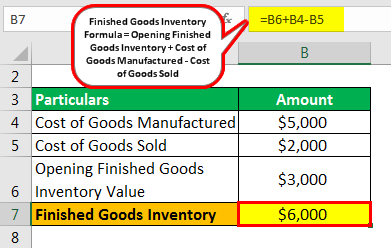

Cost Of Goods Manufactured Formula Examples With Excel Template

Manufacturing And Non Manufacturing Costs Online Accounting Tutorial Questions Simplestudies Com

Average Inventory Formula How To Calculate With Examples

Manufacturing Account Format Double Entry Bookkeeping

Work In Progress Wip What Is It

Wip Inventory Definition Examples Of Work In Progress Inventory

Cost Of Goods Sold And The Income Statement For Manufacturing Companies Accounting In Focus

Inventory Formula Inventory Calculator Excel Template

Work In Progress Meaning Importance Accounting And More

3 Types Of Inventory Raw Materials Wip And Finished Goods Youtube

Finished Goods Inventory How To Calculate Finished Goods Inventory

What Is Inventory Turnover Inventory Turnover Formula In 3 Steps

Work In Process Wip Inventory Youtube

Finished Goods Inventory How To Calculate Finished Goods Inventory

Work In Progress Wip Formula And Inventory Calculator Excel Template

What Is Work In Process Wip Inventory Definition Formula And Benefits Article

Cost Of Goods Manufactured Formula Examples With Excel Template

Cost Of Goods Manufactured Formula Examples With Excel Template